- Black basalt

- Grey basalt

- Granite Product

- Lava stone

- Soaping stone

- Slate&Quartz

- Sandstone

- Pabblestone&Gravel

Your location: Home >> Bluestone>> Quality Control Standard

· Quality Control Standard

Quality Control Standard :

Freedom Stone provides impressive after-services according to our every project " Quality comes first ,services comes first," helps Freedom Stone enjoy a great reputation among customers and in the engineering field. We always carry out International Quality Standard Level to satisfied with the customers' need.

Our Quality Control Department is responsible for quality testing of all stone raw materials and finished products,Before shipment, All products will be checked and inspected seriously by our professional and skilled Quality Controller (QC), according to strict quality control system during processing, packaging, Container loading, Our supervisors We could take and send the photos of stone products, goods packing, container loading to customers if required by customer, Meanwhile, we also welcome clients to monitor product quality by either personally visiting our production areas or employing third party independent inspection companies. Each order will be followed and monitored from beginning to end by experienced QC inspectors to ensure quality standards and punctual delivery.

Stone should be grade A quality, and the finishes as follows:

Polishing:

Polishing will be uniform throughout the slabs/tiles and in glossometer as:

For black slabs / tiles : polishing +95 in glossometer

For colored slabs/ tiles : polishing +85 in glossometer

There should be no grinding wheel marks on the polished face.

Flaming:

Flaming will be uniform throughout the slabs/tiles and brushed evenly on slabs after flaming

Thickness:

+/-1.0mm in tolerance for slabs;

+/-0.5mm in tolerance for tiles

Diagonal Out:

+/- 0.5mm in tolerance for tiles

Flatness:

If length <= 400mm,flatness tolerance: +/-0.2mm

If 400mm < length < 1000, flatness tolerance: +/- 0.5mm

If length >= 1000mm, tolerance: +/- 0.8mm

Length And Width:

+/- 0.5mm in tolerance for tiles and slabs (not apply to the random edge slabs).

Front Edge Defect:

Not allowed for slabs and tiles.

Front Corner Defect:

Not allowed for slabs and tiles.

Unpolished Side:

The unpolished side of the slab/tiles should be flat and smooth.

Crack:

Not allowed for slabs and tiles.

Crack Looks Treatment:

If slab/tile have crack looks (not the real crack, like paper been foddered but not tear down), please treat it.

Surface Treatment:

If it is possible, treat the slab/tile surface after it has been polished. So there is no little dent. This treatment is not required, but is recommended.

Billed Area Defenation:

For slab size > 1.2m x 2.2m, there should be a 1" (2.54 CM) allowance on each side of the slab to be taken out for the actually billed area.

Polishing will be uniform throughout the slabs/tiles and in glossometer as:

For black slabs / tiles : polishing +95 in glossometer

For colored slabs/ tiles : polishing +85 in glossometer

There should be no grinding wheel marks on the polished face.

Flaming:

Flaming will be uniform throughout the slabs/tiles and brushed evenly on slabs after flaming

Thickness:

+/-1.0mm in tolerance for slabs;

+/-0.5mm in tolerance for tiles

Diagonal Out:

+/- 0.5mm in tolerance for tiles

Flatness:

If length <= 400mm,flatness tolerance: +/-0.2mm

If 400mm < length < 1000, flatness tolerance: +/- 0.5mm

If length >= 1000mm, tolerance: +/- 0.8mm

Length And Width:

+/- 0.5mm in tolerance for tiles and slabs (not apply to the random edge slabs).

Front Edge Defect:

Not allowed for slabs and tiles.

Front Corner Defect:

Not allowed for slabs and tiles.

Unpolished Side:

The unpolished side of the slab/tiles should be flat and smooth.

Crack:

Not allowed for slabs and tiles.

Crack Looks Treatment:

If slab/tile have crack looks (not the real crack, like paper been foddered but not tear down), please treat it.

Surface Treatment:

If it is possible, treat the slab/tile surface after it has been polished. So there is no little dent. This treatment is not required, but is recommended.

Billed Area Defenation:

For slab size > 1.2m x 2.2m, there should be a 1" (2.54 CM) allowance on each side of the slab to be taken out for the actually billed area.

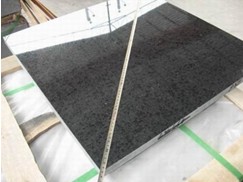

Measure Thickness:

Quality Controlling:

Coryright FDM STONE, All rights reserved

Tel : (+86) 592.5657322/, Fax : (+86) 592.5657322 , Add: Room 405-410 in Xintai Building,No.5 Yuehua Road,Huli District,Xiamen,China (Post 361013)